OUR PRODUCTS & SERVICES

FICOTEQ is fully committed to customer satisfaction while focusing on detailed design and project execution for the supply of equipment and/or packages for Oil & Gas Industries.

We manufacture and supply equipment based on our client’s design or all-inclusive services from engineering up to completion.

Equipment Design

We’ll take into consideration every relevant aspect of our client’s process, including safety aspects, siting, and equipment sizing based on our experience to design solutions according to customer specifications, industry codes, and standards. From software that improves productivity and efficiency, to the modeling, design, analysis, and simulation services that are crucial to a project’s success, we’re here to help you meet the toughest midstream engineering challenges. The FICOTEQ’S team is ready to work around the world to deliver the solutions you need to achieve your goals.

Process:

Mechanical Design

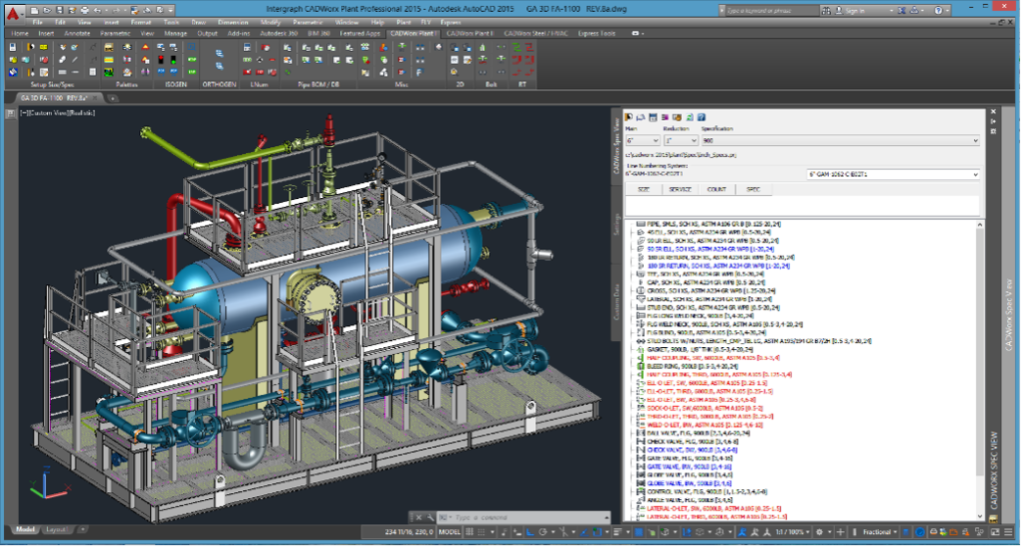

3D Modeling

Equipment Fabrication

FICOTEQ manufactures pressure vessels that are ASME Section VIII Division 1 “U” Stamped. In accordance with ASME Section VIII Division 1, these pressure vessels are used to contain gases and liquids for a variety of applications. We offer extensive expertise in the mechanical design of ASME pressure vessels that will meet rigorous quality standards and procedures and are guaranteed for a long, trouble-free vessel life.

We ensure strict adherence to ASME Code Rules and thorough testing of materials and welds yielding high-quality products and long-term customer satisfaction.

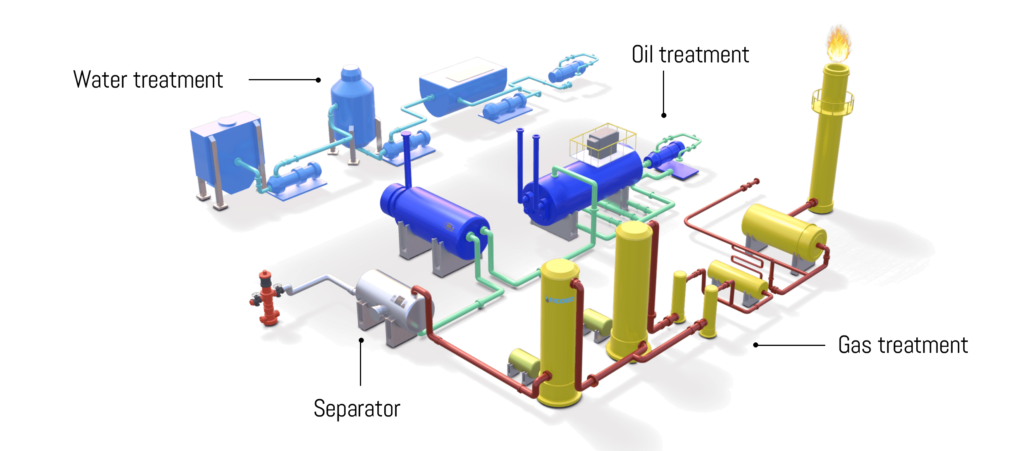

We fabricate the modular equipment for the Oil & Gas sector from client’s design or from FICOTEQs own designs. Some examples are:

Quality Assembly Process

Higher quality fabrication is achieved through the controlled fabrication of the plant without interrupting or shutting down pre-existing operations. Modular skid fabrication follows ASME code guidelines and an Inspection and Test Plan (ITP) so the quality of the assembly is reliable. FICOTEQ counts on exceptional skilled engineers and technicians who specialize in the process of designing and constructing modular skid-mounted plants. The final product will comply with the same regulations and codes that apply to traditional stick-built plants for ultimate reliability.

FICOTEQ provides excellent designs, quality, and warranty. We build to last, with many years in the business, FICOTEQ provides High-Quality equipment fabrication. We also have construction and installation specialists that can assist you with the commissioning and start-up process.

Project Management

Within the Project Management scope of work, FICOTEQ will ensure that your project is executed within budget and delivered on time:

Procurement

When you partner with us, you let your management team focus on their core business while we handle the procurement and supply of non-core purchases. FICOTEQ will negotiate the best deal, and then coordinate the purchase at every stage of the supply process ensuring good quality and timely delivery of components required for the project.

We help you in purchasing but not limited to the following:

We also manage subcontracts for:

General

Equipment

General Equipment

Separators

Indirect Heaters

Metering Skids / LACT Units

Slug Catchers

Sand Traps

Chemical Injection Packages

Filters

Piping

Oil Treatment

Packages

Oil Treatment Packages

Heater Treaters

FWKO

Electrostatic Treaters

2 & 3 Phase Separator with Cyclonic

Gas Treatment

Packages

Gas Treatment Packages

Glycol Units

J-T Units

H2S Membranes

Amine Units

Refrigeration

CO2 Membranes

Produced Water Treatment Packages

Produced Water Treatment Packages

Skim Tank

Nutshell Filter

Liquid-Liquid Hydrocyclone

Corrugated Plate Interceptor

Solid-Liquid Hydrocyclone

Induced Gas Flotation Unit

Sea Water

Treatment Packages

Sea Water Treatment Packages

Basket & Coarse Strainer

Cartridge Filter

Gas Strip Deaeration

Media Filter

Ultra-filtration

Vacuum Deaeration

6 Steps To

Your System Solution.

Click each one to know more in detail.

Interested? Send us a message.