ABOUT US

FICOTEQ is a company focused on the design and supply of equipment for Oil & Gas and Energy Industries. It is formed by engineers and professionals with extensive experience in design, manufacturing, operations, maintenance, and services of process equipment.

FICOTEQ offers competitive prices, high-quality engineering & fabrication, and on-time delivery of projects. Equipment and products are designed and manufactured in accordance with the latest code and international standards.

FICOTEQ is ISO 9001:2015 Quality Management System CERTIFIED.

OUR MISSION

To exceed our customer’s expectations in quality, delivery, and costs through continuous improvement and customer interaction. To fulfill this mission, we will treat our principals, employees, suppliers and contractors fairly and involve them in the quality improvement process to insure better responses and cost-effective project executions.

OUR VISION

To become one of our client’s preferred vendors through our added value in providing excellent services, cost-effective, high-quality, and on-time delivery of products.

Our values are engrained in the name of the company: FICOTEQ.

Focus

We are committed to providing best results for every client we serve.

Integrity

Do the right thing. Never compromise integrity and ethics for profit.

Commitment

Committed to providing the best results all the time.

Optimize

Get it done and make the best effective use of resources.

Teamwork, Talent, Trust & Transparency

We believe our team and partners are the key to success.

Excellence & Empowerment

Striving for excellence motivates & empowers our team.

Quality

Quality is always the results of excellent work without compromise.

POLICY STATEMENT

Health, Safety & Environment

In FICOTEQ, we are committed to the protection of lives, environment and properties. Safety is the priority and part of every operation and everyone’s responsibility at all levels.

Meet Our Leadership

Chief Executive Officer

Arnel has more than thirty-eight years of professional experience in Energy and Oil & Gas Industries. He held the position of VP of Engineering & Operations at Prosep, prior to co-founding FICOTEQ and AGA Process. He also worked for NATCO/Cameron for 18 years in a variety of roles in Canada, USA, Mexico, executing projects worldwide.

Strong knowledge in equipment design, Oil/Gas/Water Treatment packages, plant operations and debottlenecking. Experienced with separation equipment, including the design of high-efficiency cyclonic internals and other process equipment. Familiar with standards and codes as ASME Sec. VIII Div.1, PED, ISO, NACE, as well as major oil producer’s standards such as PEMEX, Petrobras, Saudi Aramco, PDVSA, and ExxonMobil.

Chief Operating Officer

Diego is a co-founder of FICOTEQ and has more than twenty-eight years of experience in the Oil & Gas industry. Prior to co-founding FICOTEQ, Diego worked as an independent contractor and as an employee for NATCO/Cameron executing projects for multiple NOCs and IOCs globally, as well as Baker Hughes, and other international EPC firms. He has a strong knowledge of equipment design, plant operations, project management, and equipment manufacturing.

Experienced with separation equipment including process plant conceptualization, design of separators, high-efficiency separator internals, electrostatic treaters, heaters treaters, hot oil systems, line indirect heaters, Gas/Oil/Water Treatment, gas compression packages & other process equipment. Expertise with pressure vessel design using international codes and standards such as ASME Sec. VIII Div.1/2, ISO, NACE, ASME 31.3, and multiple major oil producers and EPC standards (Ecopetrol, Pemex, SLB, Cameron, and others).

Water Treatment Specialist

Raúl has over thirty years of experience in the Petroleum Industry specializing in process and mechanical design of produced water and sea water treatment equipment for onshore and offshore projects. His experience includes technology selection, equipment sizing, process design, mechanical design, estimation, project execution, project management, training, commissioning, start-up, and product development.

Positions held include Proposal Engineer, Process Engineer, Application Engineer, Water Treatment Department Manager in North and South America, and Center of Excellence Sea Water Treatment North, and South America for onshore and offshore projects.

Crude Treatment Specialist

Marlene has more than fourty years of professional experience in the Energy and Oil & Gas Industries. She held the position of Principal Engineer at Schlumberger from where she retired, prior to joining FICOTEQ as a Process Consultant. She also worked for NATCO/Cameron, Prosep as Principal and Senior Process Engineer in the separation process and in PDVSA for 20 years in all processes of oil and gas production operations in Venezuela.

Strong knowledge in equipment design, process plant conceptualization, design of separators, high-efficiency internals, electrostatic treaters and desalters, heaters treaters, hot oil systems, FPSO equipment design, and applications. Expertise in oil chemical treatment, chemical selection, and formulation for production operations. Familiar with international standards and codes like ASME Sec. VIII Div.1/2, ISO, NACE, Norsok, as well as major oil producers and EPC standards such as BP, Chevron, Modec, Pemex, Petrobras PDVSA, SBM and Shell.

Chief Technology Officer

Francisco has 34 years of experience in the oil and gas industry performing multiple roles in different companies such as PDVSA (Corpoven), PECOM Energy, and Petro Equipos de Venezuela, working on applications for crude oil dehydration and desalting, technology evaluation, and oil field development of infrastructure and services.

He worked for SLB for 18 years, going through multiple acquisitions (Natco, Cameron, Schlumberger). He is a subject matter expert in electrostatic dehydration-desalting processes, production facilities design, operation/optimization for onshore, offshore, and refinery domains, with focus on new product and technologies development. He is also a Certified PMP® for over 17 years with a long trajectory of international project execution.

Managing Director - Middle East

Firas Aldahshan has over twenty-five years of experience in the Petroleum Industry specializing in the field of O&G production and treatment with focus on produced water and oilfield water management. His experience includes oil and gas technology application, Engineering Solutions, client management, strategy development, and techno-commercial tendering.

Held key technical and management positions in Cameron, Natco, SLB, Veolia, Enerflex and Siemens including Director of Sales & Business development, and business management. Worked in USA for over 10 years, and in the middle east for over 16 years.

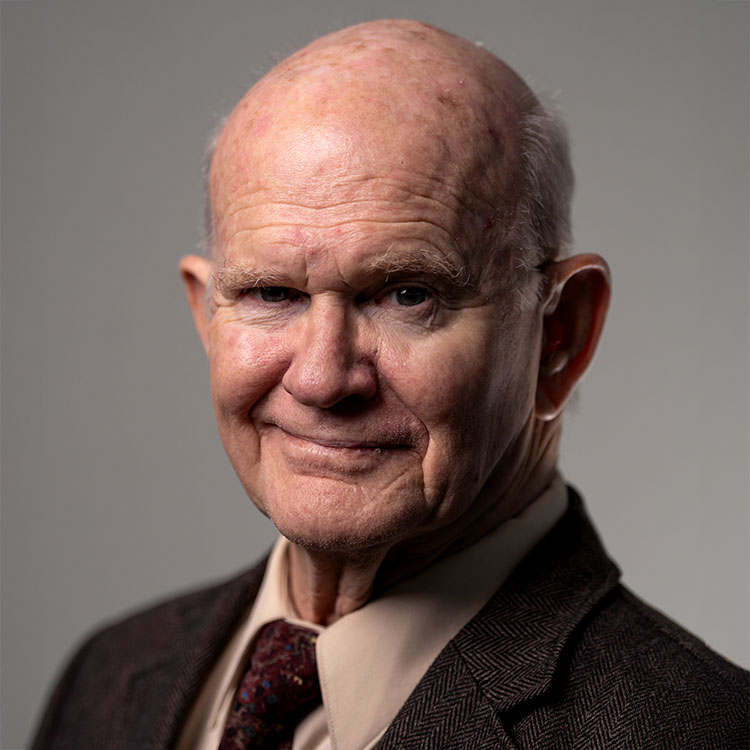

Electrostatic Technology Advisor

Carroll has forty-five years of experience in oil dehydration and desalting processes. Starting with the development and field testing of demulsifier chemicals used in oil dehydration, product design, and engineering for all types of oil dehydration and desalting equipment, product management, and project management. Projects spanning the world including the North Slope of Alaska, North Sea, Mideast, Kuwait, Saudi Arabia, UAE, Egypt, Europe, South America (Colombia, Brazil, Ecuador, Venezuela, Peru, Chile), Angola, the Congo (DRC), Chad, Mexico, Japan, South Korea, Gulf of Mexico.

Caroll worked for CE Natco–Cameron for an impressive 45 years, leading the way Electrostatic dehydration and desalting evolved from the main technology providers during those years and participating in every relevant project in the history of electrostatic treaters.

Technical Advisor/Partner

Hugh West is a Mechanical and Chemical Engineer and worked for Shell Canada for 27 years in a variety of roles including lead machinery engineer, lead reliability engineer, and Engineer at Large Scotford Complex where he led multidiscipline teams to resolve the most complex plant problems.

After retiring from Shell, while working with Natco for 7 years, Hugh developed 6 patents as the sole inventor in the area of liquid, gas, and solids separation. Natco retained the rights. He has also invented a reciprocating compressor valve capable of increasing flow by 28% and has redesigned from scratch a significant process reactor, increasing run life by a factor of five.

More recently, Hugh was with North West Redwater Partnership as a rotating equipment engineer for 5 years. He has assisted in the commissioning of multiple plants, two refineries, one upgrader, and one primary extraction.

Interested? Send us a message.